FEATURES AND TECHNOLOGICAL AREAS

OVERHEAD CRANES EQUIPPED WITH LIFTING MAGNETS FOR MATERIAL HANDLING.

Manpower involvement in material handling has always been a risky affair. In order to eliminate this we came up with lifting magnets, which helps to load and unload materials without human involvement. Through this we have been able to reduce the process cycle time and prevent damages in loading and unloading activities.

AUTOMATIC TEMPERATURE CONTROLLED BURNERS (DANIELI- ITALY)

The implementation of auto-controlled burners has enabled us to do saving on the production cost and also eliminate excessive combustion of furnace oil. Also, this has allowed us to reduce the size of the furnace.

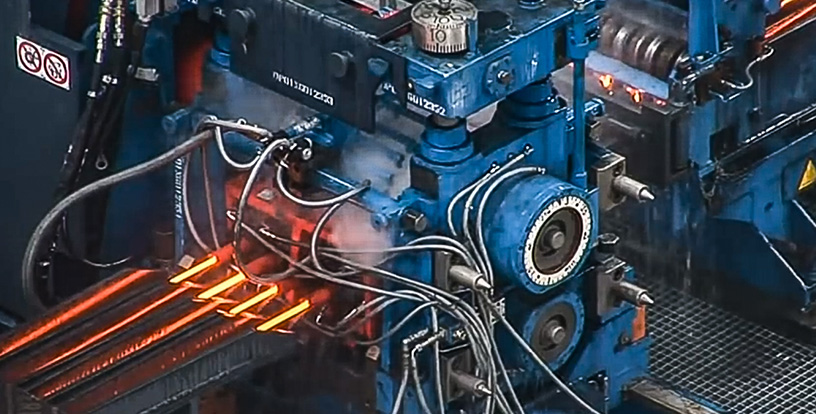

HORIZONTAL-VERTICAL STAND ARRANGEMENT FOR ROLLING

Coming out from the conventional rolling system, company decided to install horizontal-vertical stands for rolling (Danieli- Italy).With this smooth rolling system, we were able to develop the shaping process, And to maximize the quality standards.

MULTI-SLITTING TECHNOLOGY

As an organization, MELWA initially accommodate the multi-slitting technology rolling process in Sri lanka (Danieli- Italy). Through this the company was able to increase the production without increasing the mill speed or any other factors. By this technology we do 2 slit for 12mm, 3 slit for 10mm and 4 slit for 08mm bars.

AUTOMATIC BAR COUNTER

MELWA installed an automatic bar counter at the finishing area to count the finished bars. This has enabled us to reduce the cycle time of the process. This bar counter comes with a Swedish technology which uses laser technology to count the bars.

AUTOMATIC BUNDLING MACHINE

The automatic bundling machine is the first of its kind in Srilanka. This machine is originated in Sweden and has helped us to reduce the cycle time in the material finishing area.